ABOUT PEDDILASER

The Ultimate Laser Cutting Machines for Industry Leaders

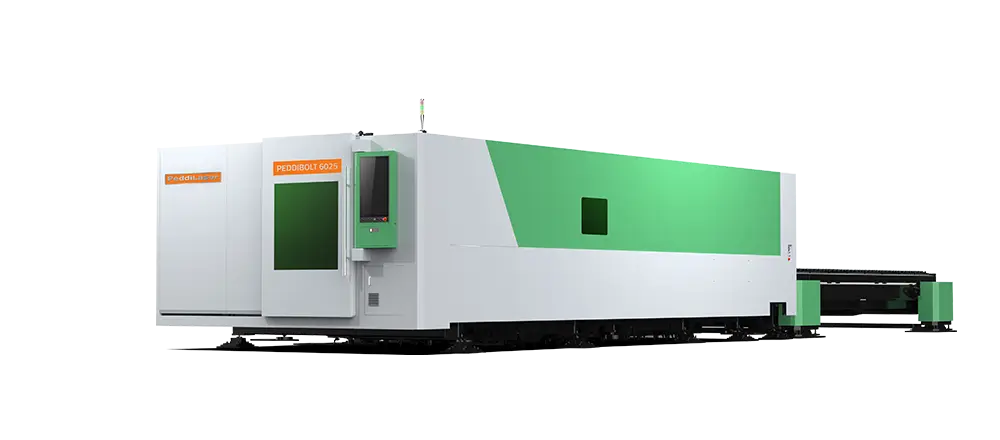

PEDDIBOLT

A high-performance, highly efficient, and dynamically powerful 2D laser cutting machine.

View MachinePEDDIWPC

Capable of efficiently cutting large-diameter, heavy-duty, and extremely long tubes/pipes.

View MachinePEDDILS

A high-speed tube and profile laser cutting system built for precision, automation and versatility.

View MachineAdvanced Technology

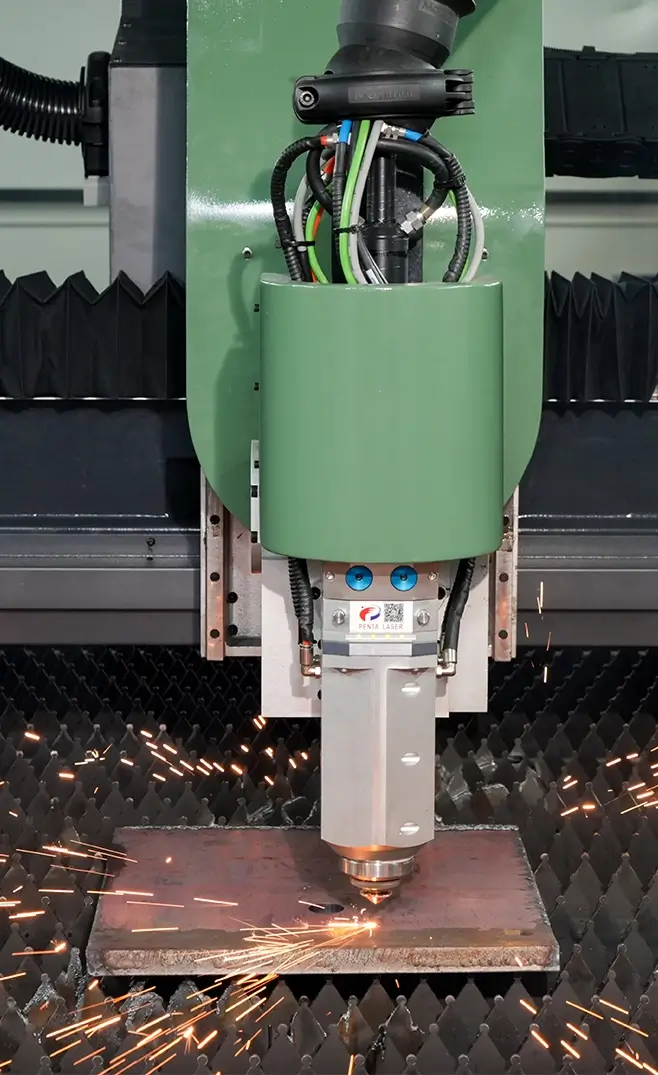

Super Fast Laser Cutting

The super-fast cutting technique is an exclusive innovation of the PeddiLaser system, offering unparalleled displacement dynamics and high acceleration capabilities, particularly when cutting small holes and complex shapes. This advanced method significantly enhances cutting efficiency. When compared under identical cutting process parameters, the PeddiLaser's super-fast cutting technique boosts cutting efficiency by an impressive 30-200%.

Advanced Technology

Ultra-Hyper-Clean Cutting

Ultra-clean cutting is an advanced carbon steel cutting technique developed by BTP and integrated into the PeddiLaser system. This method surpasses oxy-fuel cutting by achieving speeds that are 100-500% faster. Additionally, it produces superior cutting sections with virtually no burrs, outperforming traditional air cutting.

Advanced Technology

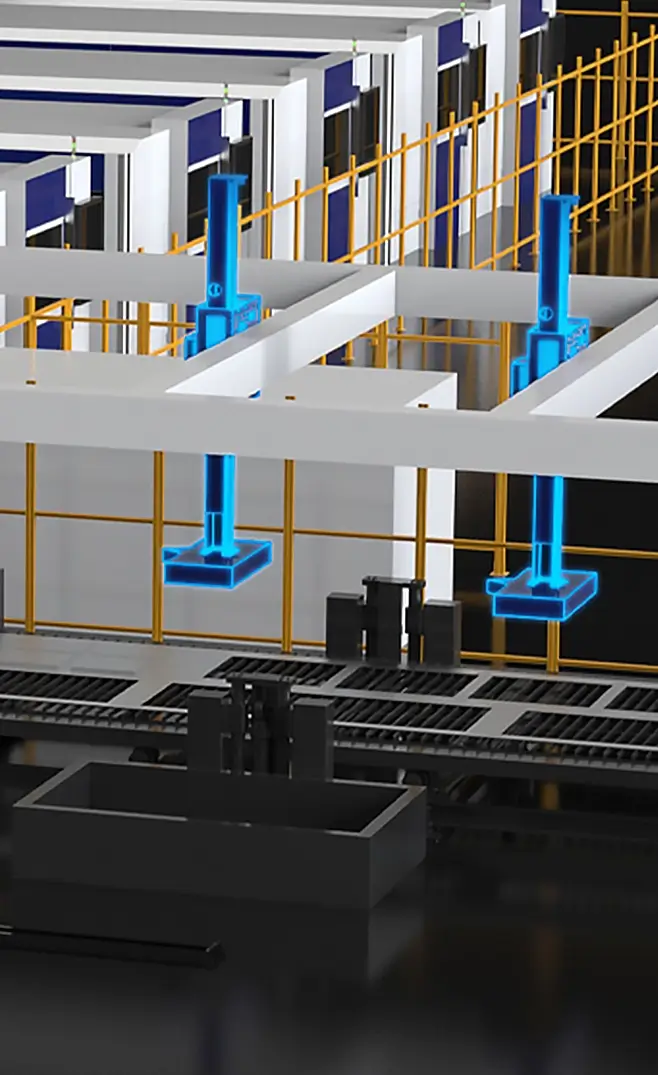

Automation with Laser Cutting Flexible Production Lines

The laser cutting flexible production line consists of one or multiple laser cutting machines, automated material storage, automated loading and unloading systems, monitoring systems, etc. The modular design and intelligent control enable networked management of the system.

Laser-Crafted Success: Customer Journeys

Travis Kerr

Owner - Kerr²

Thomas Tebbens II

CEO - Tebbens Steel